Products

Recipe conveyor RB

The recipe conveyor is provided with 4 load cells

Loose-leaf products are discharged manually or from an infeed conveyor onto this belt. Either after a predetermined period or

continuously, this weighing conveyor discharges the product on, for example, an elevator belt.

The programme of the weighing conveyor is processed in the central control box.

In case of manual discharge and/or mixing, the touchscreen (option) is used to indicate which product in what amount needs to be added. The programme allows storage of various recipes.

CEA Harvester CH-30

Harvester

The CEA Harvester is used to harvest product grown in the greenhouse.

Gutters are fed to the machine by a conveyor, and perfectly aligned with the center of the cutting area. Two circular knives, slightly positioned above the gutter are also height adjustable, cutting the leaf from the stem.

The leaves fall onto a collection conveyor, which brings them outside the machine onto a conveyor forfurther processing. The gutter passes through the machine and collects from the other side.

At the cutting area,

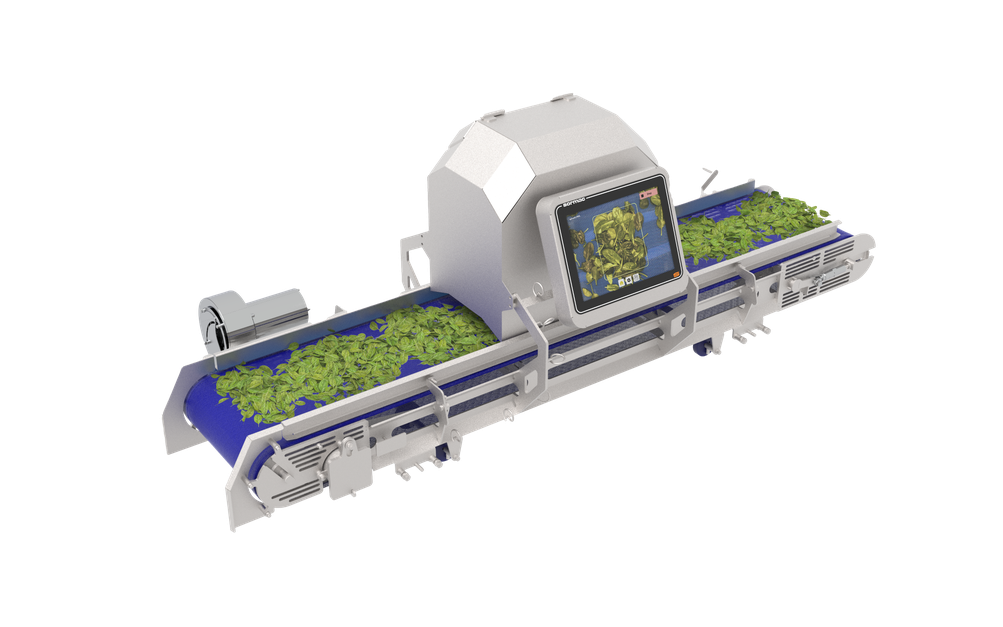

OptiPro

An AI-powered technology designed to minimize manual handling and automate quality control. Using high-resolution cameras and deep learning algorithms

Sormac’s OptiPro visual automation system, an AI-powered technology designed to minimize manual handling and automate quality control. Using high-resolution cameras and deep learning algorithms, OptiPro verifies the product against pre-set recipes and monitors the harvesting process in real time. It checks the integrity and positioning of each gutter and communicates with the central control panel to adjust processing parameters if necessary. This intelligent oversight enables dynamic line adjus