Optimizing Greenhouse Efficiency with Digital Twins

Priva

PrivaIn the realm of building management, the digital twin technology has emerged as a groundbreaking force, reshaping traditional methods of energy management and resource allocation. Now, its transformative potential is expanding also to the greenhouse industry, already realizing significant energy cost savings.

At its core, a Digital Twin is a virtual replica of a physical system or process, which is continuously updated and trained with real-time data from sensors and other sources. Digital Twins offer the possibility to test the impact of different scenarios to define the one with the best outcomes before putting it into practice.

What does a Digital Twin of a greenhouse look like?

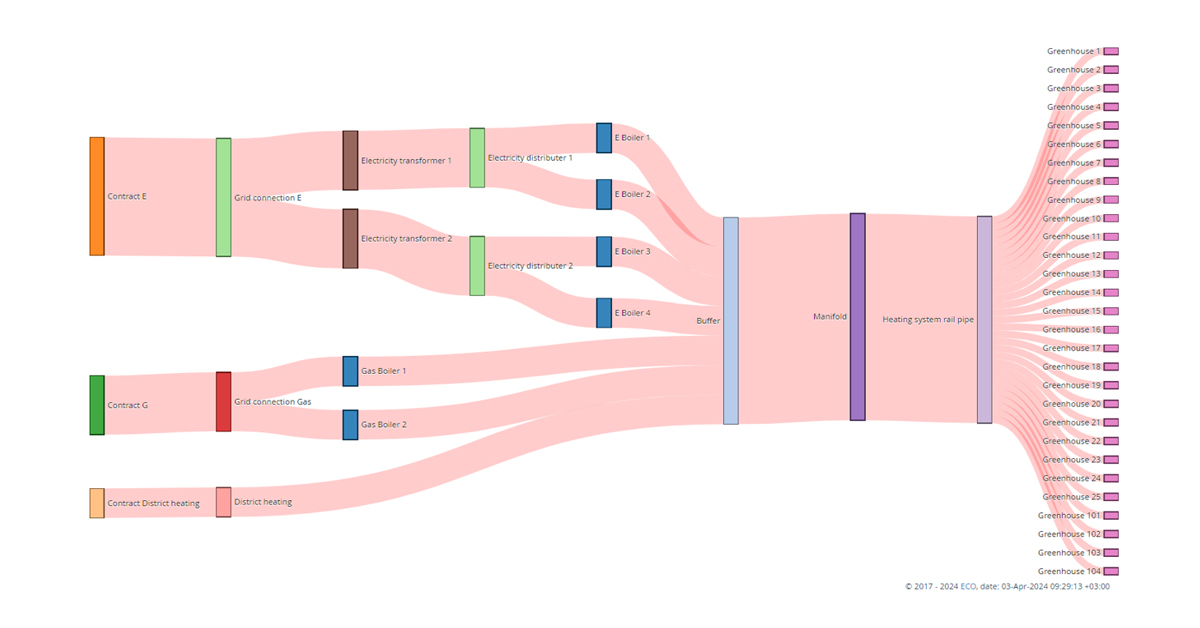

In the context of greenhouse energy cost optimization, the Digital Twin contains all the knowledge of a greenhouse and energy installation, including energy contracts (e.g. capacities and configurations of gas boilers, e-boilers, heat pumps and buffers). Being integrated with the operational control of the climate computer, it also considers the location and characteristics of the greenhouse, its light consumption, energy screen usage and weather forecasts. This makes the Digital Twin very smart, without influencing the climate and crop strategies of the trusted process computer.

How does it work?

In practice, the digital twin technology used by Priva Energy Cost Optimizer (ECO) proactively purchases from the grid energy or heat when prices are low, storing it in a buffer to be used at a later moment. This dynamic energy management approach not only minimizes costs but also saves energy because of good housekeeping. Based on accurate forecasts, only the actual energy required for the next 24 hours is purchased and no heat goes to waste. Even more savings on the CO2 footprint can be realized when green electricity is a primary energy source.

Proof of concept

Seedling grower Sigg-Plant in Finland was interested to use more green energy and asked to their installation partner to install multiple e-boilers. In addition, they asked Priva to apply their ECO Digital Twin technology that already had a successful track record in building automation. The engineers built a digital twin of the greenhouse and its energy installation, including external energy sources and contracts. When the digital twin was activated in January, it started to save energy costs immediately.

Savings of over 25% in practice

The digital twin technology used by Priva Energy Cost Optimizer (ECO) enables Sigg-Plant to automatically buy energy from the grid when prices are low and store the produced heat in a buffer to be used at a later moment. The results are stunning: in the first quarter of 2024 Sigg-Plant has already saved over 85.000 Euros in energy costs (more than 25%) and over 300.000 kg of CO2. Of course, the savings achieved may vary depending on the differences in installation and local energy pricing dynamics. Integrating additional installation components such as lighting systems and combined heat and power units (CHP) in the Digital Twin will create even more possibilities to optimize energy costs.

Toward predictive cultivation

Optimizing energy costs is the first implementation of Digital Twin technology in horticulture. Future applications of Digital Twin solutions are expected to encompass a broader scope of optimization tasks, ranging from resource allocation and predictive maintenance to predictive cultivation.

In essence, digital twin technology represents a paradigm shift in greenhouse management, unlocking unprecedented levels of efficiency and productivity. As the journey of innovation continues, the applications of Digital Twin technology in horticulture will unfold, entering a new era of predictive, scalable and sustainable cultivation practices.

Sankey diagram: a visual representation of the digital twin showing the interaction between energy contracts, grid connections, weather, energy installation (e.g. heating buffer and heating pipes) and the final destination for the heat, the greenhouse.

.png?h=628&iar=0&w=1200)