Hydrogen: refuel at the grower!

Author: Jacco Strating

Author: Jacco Strating'Passion' embodies our unlimited commitment to crops, people, and technology, driving innovation across the horticulture sector. Building on the enduring importance of personal touch, GreenTech is excited to strengthen connections and unveil new initiatives designed to inspire growth and collaboration within the industry. In a series of articles, the passion within horticulture worldwide will be highlighted from different angles. This article focuses on the search for sustainable energy sources and a Dutch project that enables consumers to charge their cars with hydrogen from the grower.

Anyone who visited GreenTech Amsterdam last June couldn't have missed the truck in Hall 5, with the sign ‘Refuel at the Grower’. The truck was parked there by Division Q, a project organisation for sustainable and technical innovation in greenhouse horticulture. Division Q is a spin-off of the Dutch cress producer Koppert Cress. Together with this company and other pioneers in the sector, it is launching projects in areas such as energy, water/crop protection, and mechanisation. It is also investing in start-ups and technologies for future-proof horticulture.

Sustainability efforts

There's currently a lot of innovation going on concerning energy, says Bart van Meurs, General Manager of Division Q. This applies to both the development of new technologies to reduce energy demand in greenhouses (think about low-emission glass, screens, PCM heat batteries) and to making the energy supply more sustainable (think about geothermal energy, Medium Temperature Storage, and High Temperature Storage). "It's striking that the innovation isn't just about experimental development; practical application is also accelerating. Social pressure and tax measures are pushing the horticultural sector to continue its sustainability efforts and maintain its focus on fossil-free cultivation. The highly profitable model of heat, electricity, and CO2 production is under pressure due to the tax measures. The sector is clearly searching for the new standard."

Van Meurs sees several opportunities. “On the one hand, seasonal heat storage is experiencing a revival. In the past, this was primarily reserved for companies that actively cool, such as phalaenopsis nurseries. Now, companies are looking at other sources to ‘harvest’ this heat, such as aquathermy and solar thermal energy. It's no coincidence these are technologies for which we at Division Q have developed patented solutions are becoming increasingly popular. Medium Temperature Storage up to 50°C grows along with this revival.

Residual heat

Another major opportunity for the sector is residual heat from industrial processes, according to Van Meurs. “(Waste)water below 100°C is useless for many sectors. At the same time, the horticultural sector is drilling for geothermal energy in many places to extract water within the same temperature range. Residual heat can be used centrally, for example, through WarmteLinQ, an underground pipeline that allows heat from the Port of Rotterdam to be used to sustainably heat 120,000 homes and businesses in the region. But also decentralized: bring those processes to the nursery, or the nursery to the processes. This is exactly what we're going to do with hydrogen.”

Replacement for natural gas

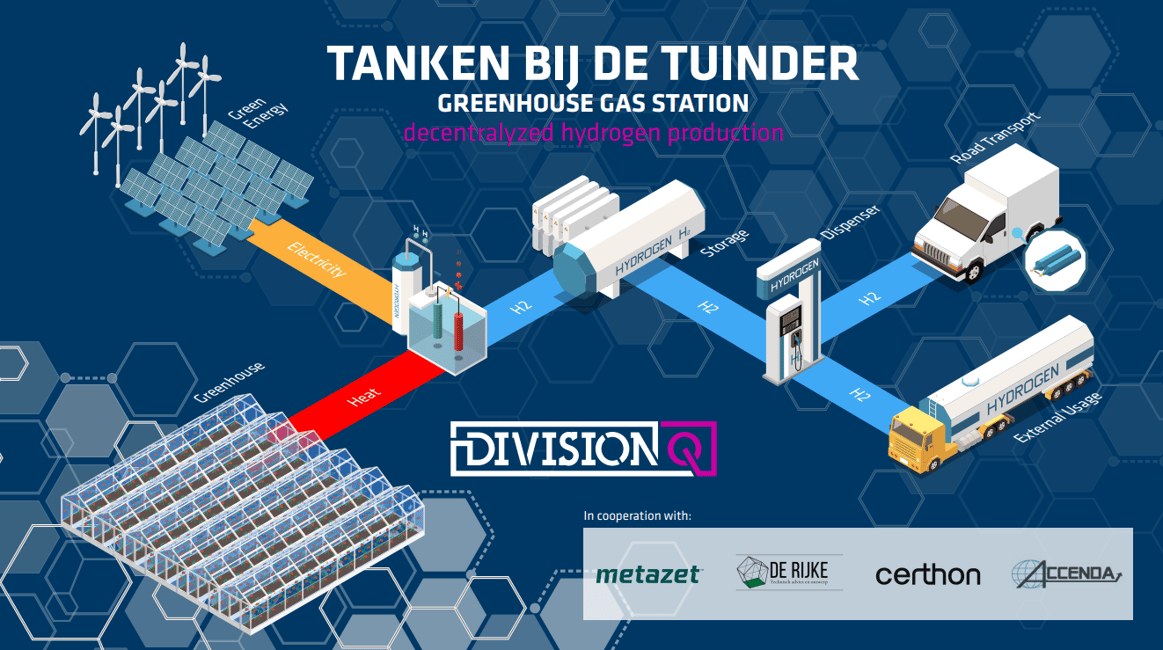

And that brings us back to the hydrogen truck, showcased at GreenTech Amsterdam this June. That truck brought the possibilities of hydrogen to visitors' attention. "Hydrogen is potentially a one-to-one replacement for natural gas, but without CO2 emissions," says Van Meurs. "However, because of availability, infrastructure, and price this is still a long way off. That's why we don't see all those developed hydrogen CHPs (Combined Heat and Power Systems) in practice yet." There is, however, a growing need for green hydrogen in sectors such as industry, construction, and (heavy) transport. A common objection to hydrogen production is the loss during the conversion of water into oxygen and hydrogen. This is very useful heat for a grower. By producing hydrogen at the nursery, this heat can be utilized. “Smart integration with the grower's energy management and the connection with solar PV and, in some cases, even wind energy at the nursery make this solution competitive. Instead of burning gas, utilizing the heat, and selling the electricity, we will now convert water into oxygen and hydrogen, utilize the heat, and sell the hydrogen. Customers can literally ‘refuel at the grower’.”

It’s a visionary project - yet fully achievable. "A concrete design is ready to install a 1 MW electrolyser at Koppert Cress," says Van Meurs. "We're currently in the permitting and financing process, which we'll be working on with our project partners in the coming months. Our consortium includes Certhon, Metazet, De Rijke Techniek, and Accenda. Metazet and Koppert Cress also now have a hydrogen truck at their disposal."

Hydrogen Entrepreneurs' Group

There's a lot of interest in hydrogen from the horticultural sector, says Van Meurs. "All initiatives have been bundled by the industry organization Glastuinbouw Nederland (Greenhouse Horticulture Netherlands) in a special Hydrogen Entrepreneurs' Group. Moreover, there was a lot of interest in our hydrogen truck during GreenTech Amsterdam. On the one hand, we were able to talk to everyone there with hydrogen plans and solutions, and on the other, we were able to announce our plans to many growers. Along the way, we were also able to connect with startups and other innovators in the sector."

.png?h=628&iar=0&w=1200)