Robot automatically spaces young pot orchids right distance apart

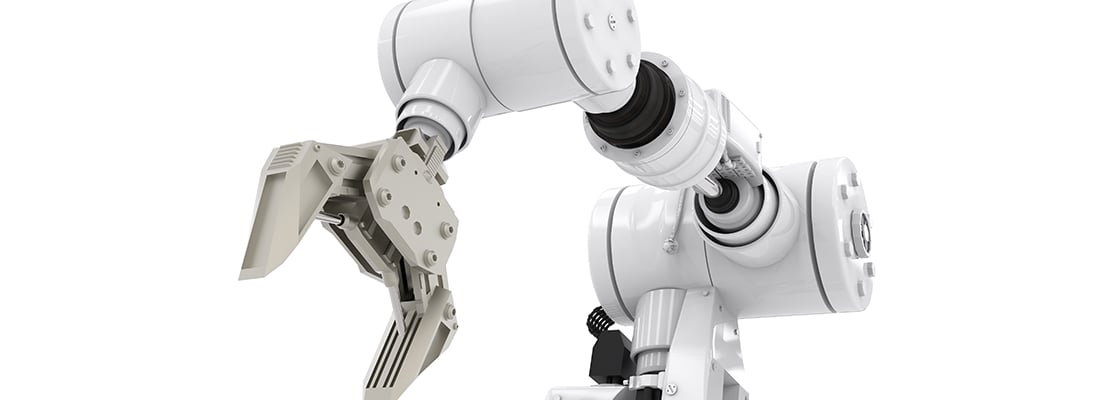

An orchid nursery in Delfauw, The Netherlands, has followed the global trend of robotisation. Hazeu Orchids have recently implemented as part of an internal transport system within their facility. The robotisation has allowed them to execute and calculate processes with mechanical proficiency and increase the safety of their plants.

Javo, a Dutch engineering firm from Noordwinkerhout, worked closely with Hazeu Orchids to develop the right system for their operation. The system was built on a Sysmac platform and involved help from Dutch based electronic component creator, Omron. With the new robot, Hazeu is able to set down between 2,000 – 3,000 plants per hour on their respective benches. It is essential to place them on these mobile benches to ensure that they are the right distance apart for optimal growth and health.

When growing orchids, one must take into account several factors about the atmosphere in order to guarantee the best growth methods; and when temperature, atmospheric humidity, and fertilisation are all taken into account, there is still one factor that is essential. The space between per plants per square metre is a critical aspect of the growing experience.

“The more growing plants you have per square meter, the higher your ultimate product will be. But you can’t place orchids too close together or they will get damaged. The leaves grow out over the side of the pot and the roots also tend to grow out of the pot and take root. This makes plants very susceptible to damage when you move them. So, before we set out the plants in the second growing area, we fit a transparent plastic collar around the plant” – Hazeu Orchids, 2017

Utilising this method allowed Hazeu to fit 65 orchids per square meter instead of 56. The next step was ensuring that throughout growth the plants would stay equally apart. This is where Javo came into the process. At Javo “We make a lot of machines for filling, moving and handling pots and trays”. The robot that was built specifically for Hazeu was the first of its kind to be built on a Sysmac platform. This allowed for it to be completely integrated into the Hazeu system, including the interface, PLCs and servo drives.

In essence, the robots operations are not overly complicated as the process, once installed, is automated and requires little attention from the workfloor. Once the pots have been fitted with their plastic collars, as mentioned above, they are placed onto a conveyer belt. The belt is built of sequential pot cups to hold the orchids in place. The plants are then lined up to a pre-determined distance, when the robot determines the plants are perfectly placed, they are moved onto the mobile rack.

A small additional feature to the robot’s programming is its ability to prevent pots from falling using a small movement. The fork of the robot picks up the row of pots and slightly bumps them against the previous row, then retreats slightly and sets down the pots. This provides enough space between rows to avoid knocking roots or leaves. This extra programming has proven to reduce the number of falling pots by 99%. A linear functional device is used to make sure that the moments of the fork and calculatedly and executed flawlessly.

Hazeu has installed a safety program to ensure that all plants receive the right treatment depending on their growth pace. Two robots have been installed to control the distribution of plants throughout the process. The robots measure the plant’s growth and determine which are big enough to move down the growing process and which ones require additional growth time in their current stage. As the robots operate remotely, maintenance and growers can monitor these functions easily and can make changes in real time.

As robotisation continues to move into the world of horticulture, it is interesting to see at which points of the supply chain will be replaced with robots and which others require strict human control.

How would you feel with the months hottest Horticulture Technology tips, trends and info at your fingertips? Sign up for our monthly newsletter to make sure you stay ahead of the game! #AskGreenTech

If you’d like to sign up for In Greenhouses newsletter, check out their subscription page for multiple options and many many interesting articles!

Source: Page 48, 49 In Greenhouses Magazine, Number 4, October 2017, Volume 6.

Author: Theo Snijders

.png?h=628&iar=0&w=1200)